Blog

POLYURETHANE AND POLYUREA SEALING MEMBRANES

In 1937, research director Otto Bayer was working on the development of a polyamide-like synthetic fiber. During his experiments he used a reactive group that formed urethane where in contact with alcohol polyurethanes were born. The use of polyurethane has been unknown for several years. After a decade of research and experimentation came the invention of its first processing machine and thus laid the foundations for current polyurethane foam products. In 1979 the first foam specially designed for building insulation was a fact.

The polyurethane membrane was developed as a product specifically designed for continuous and completely adhered sealing. This process revolutionized sealing techniques by offering a jointless system that could be adapted to any surface shape while providing excellent mechanical properties and strength. It was a significant improvement compare to existing acrylic systems, which had difficulties in flat areas without slopes.

In 1990, Mark S Barton and Mark Schlichter patented the development of two-component polyurea. The fast drying properties and resistance to moisture made it ideal for sealing large surfaces.

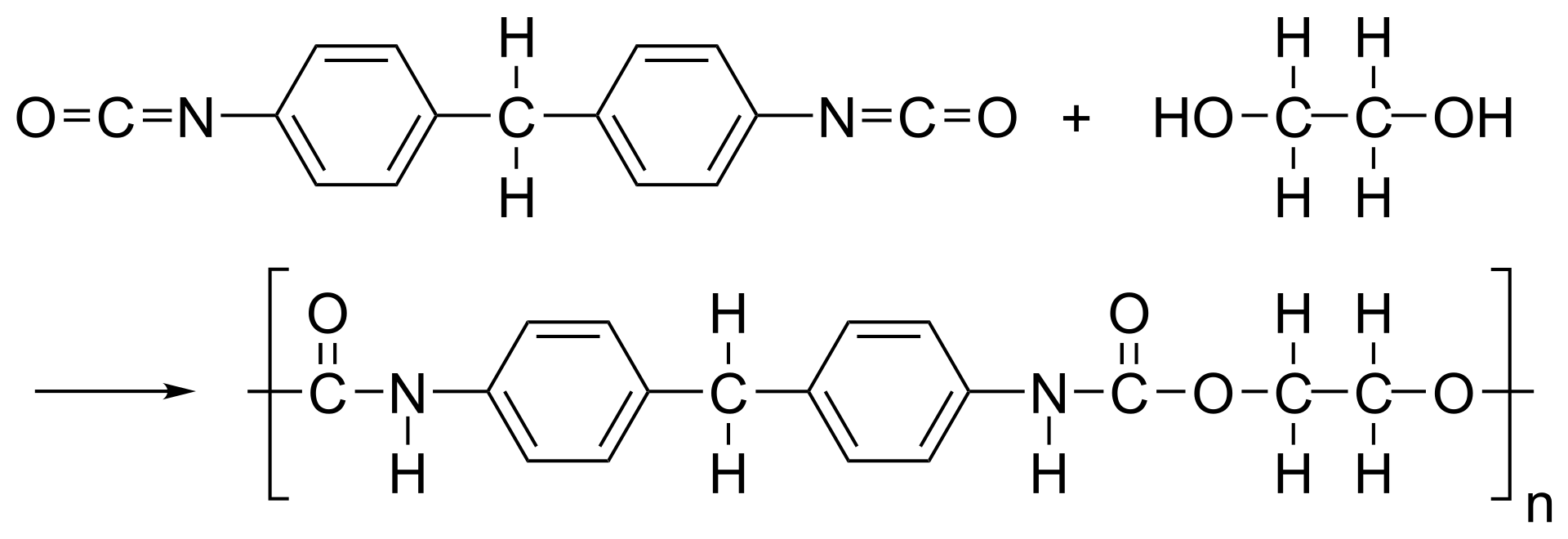

Chemical bond:

Polyurethane:

The polyurethane membrane is formed by the reaction of isocyanate and polyol in the presence of a catalyst.

Polyurethanes represent one of the most versatile polymers depending on the polyol and isocyanate used. It has the ability to obtain an infinite range of products from the most rigid to the most flexible, with polyurethane membranes being the last tip of the scale.

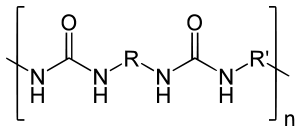

Chemical bond:

Polyuria:

Polyurea is a product of a compound between isocyanate and various polyamines. Unlike polyurethane it does not require a catalyst, as the compound is stronger and faster with double chemical bonds. It is resistant to high temperatures and humidity, although it is essential that the surface be dry to ensure proper adhesion.

Products:

- Sikalastic 612 MTC

- Tecnopol Desmopol Aromatic polyurethane for cold application

- Tecnocoat P-2049

- Sikalastic 843-GP 100% pure polyurea for hot application

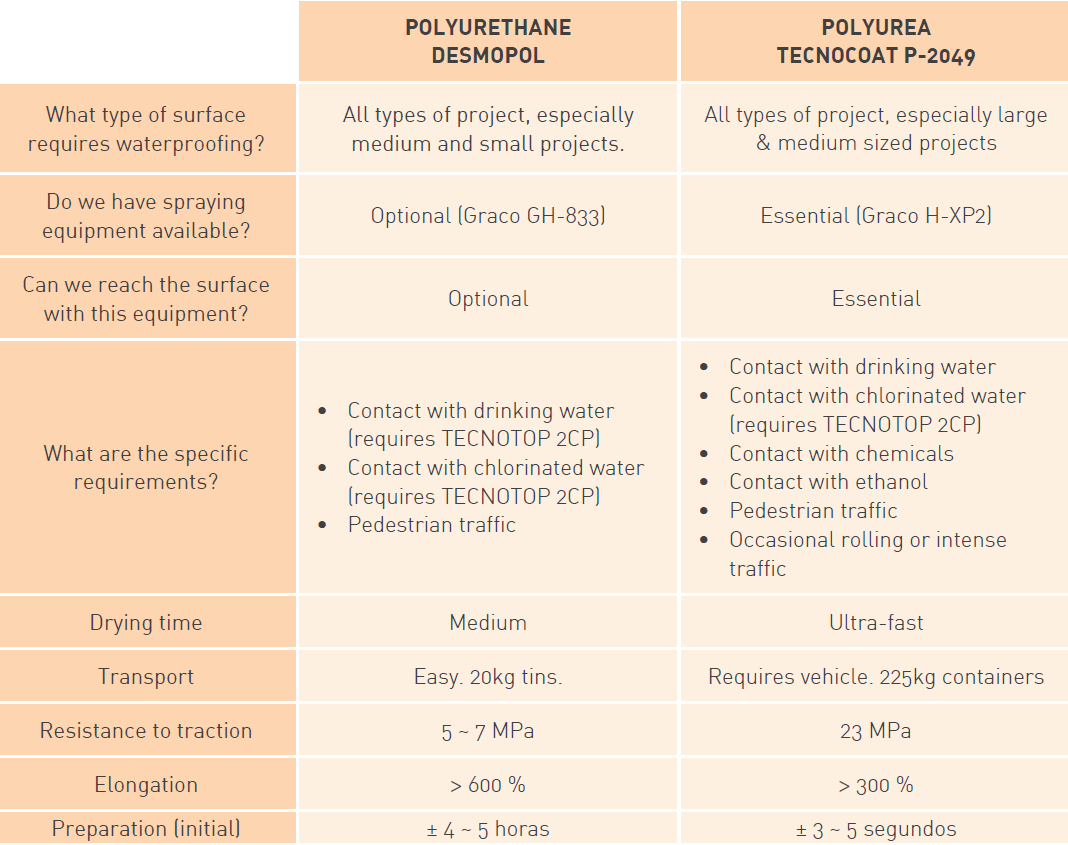

These are two sealing membranes that have very different chemical and mechanical properties. Due to their characteristics, their costs and methods of application have been designed for different purposes.

The first questions we need to ask are:

What kind of surface requires waterproofing? Do we have spray equipment available? Can we reach the surface with this equipment? What are the requirements for the job? What is the Budget?

After answering these questions and with the following table as a guide, we will be able to make a product decision that best suits our purpose.